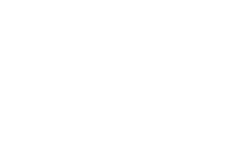

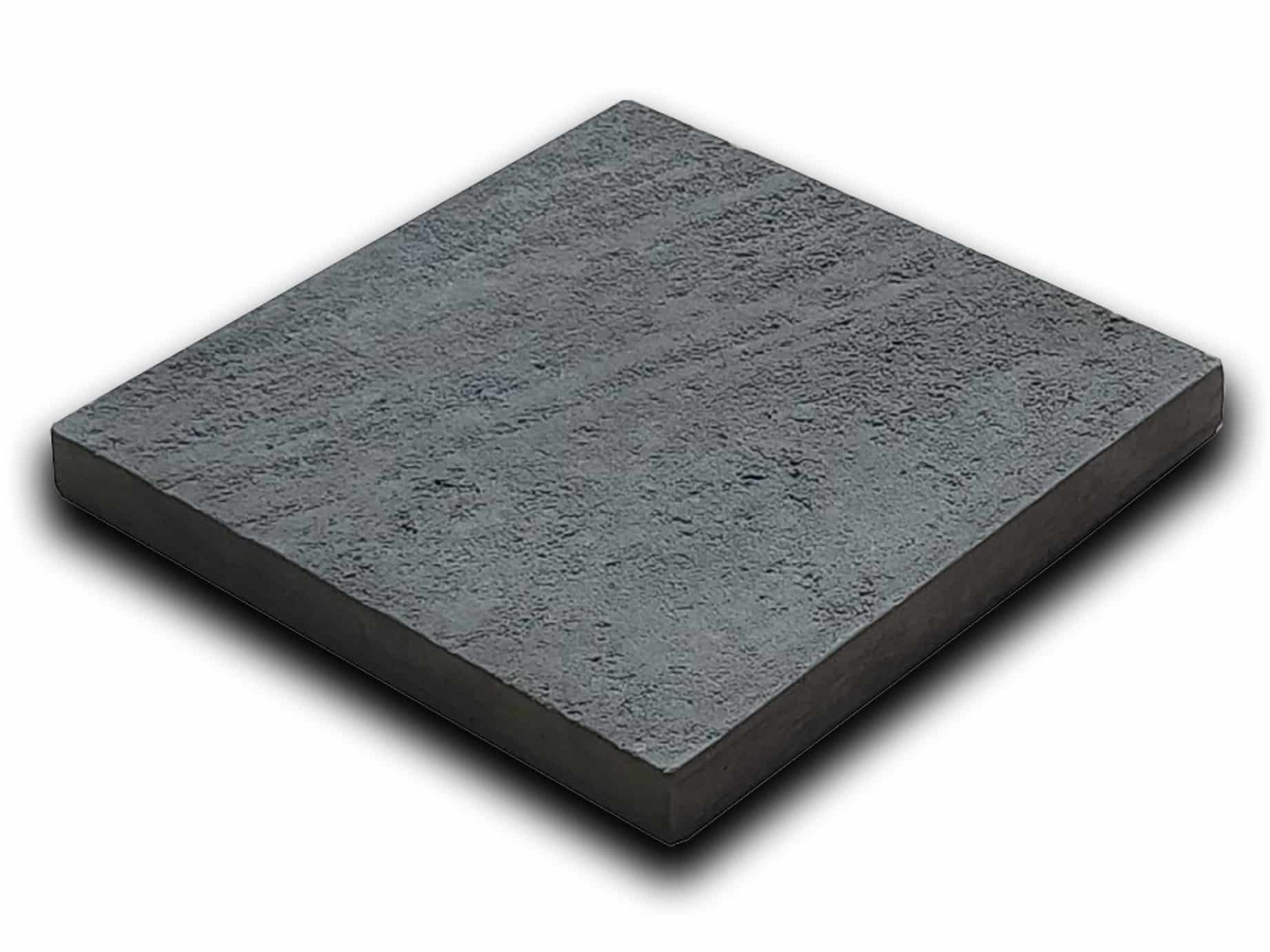

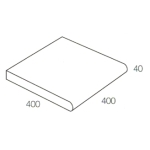

Coogee Sawcut Paver 400x400x40mm

$15.40 each

Available

Please note Whilst all care has been taken to provide you with a good indication of colour, you should always sight product samples before use, due to natural variations in Colours & Sizes. Products may vary from image provided.

m2 Calculator: (enter value in m)

Description

Provincial pavers’ finish is a work of art for outdoor creativity. A unique handmade paver emulates the naturally aged appearance of stone.

Each paver is handmade in a traditional manner.

Give character to your garden or courtyards with the natural appeal of sandstone and limestone.

Suitable for paths, courtyards, pool surrounds, steps, and outdoor entertainment areas.

Additional information

| Weight | 15.00 kg |

|---|---|

| Dimensions | 400 × 400 × 40 mm |

| Free Delivery | 4 Tonne and Over (Conditions Apply) |

| Supplier | |

| Price per m2 | $96.25 |

| Qty per m2 | |

| Application | Patios, Courtyards, Steppers, Pool Surrounds, Entertaining Areas, Pathways |

Downloads

DIY Videos

Installation Guide

Installation

Please note these recommendations are intended as a guide only and should be used in addition to the

relevant Australian Standards for trade practices. Note that installation may vary from site to site with conditions experienced on that site (i.e. soil conditions, pool surrounds, driveways etc.). The contractor should decide if these suggestions are suitable for their application or require further adjustment.

Laying on Sand

When using the flexible method it is critical to have good drainage to allow water and moisture to drain away from the paved area quickly.

For paving that will be used for light vehicles it is best to lay the pavers in herringbone, basket weave and stretch bond laying patterns.

1. The base course shall be gravel road base and be 75 to 100 mm thick. The base course shall be levelled within a tolerance of no more than 5 mm from the base of the level in any direction. It shall be of an even thickness and adequate drainage precautions taken. It should be correctly compacted to suit the intended application. There should be no ponding on the surface of the base course as this may cause problems with the integrity of the application.

2. Bedding Sand – cover the sub base with well graded coarse bedding sand. Ensure that the sand is relatively dry and spread evenly then compact

with a hand held or mechanical compactor. The thicknesses of the bedding sand should be between 25 and 30 mm thick when compacted.

3. Use a screed to level the sand and allow for a slight fall

away from any walls to ensure adequate drainage.

4. The product can be placed on the bedding sand using grid or string lines to ensure alignment.

5. The perimeter of all paved areas should be provided with edge restraints to prevent lateral spread of the tiles and consequent loss of interlock. Edge restraints should be placed within 100 mm of the subgrade and base course.

Suitable edge restraints include vertical edge bricks laid in a small concrete trench, exposed or concealed concrete beams, and walls, kerbs, e.t.c. The edge beams should be constructed using a concrete mix to the relative Australian Standards.

6. Note: It is absolutely critical for properly installed edge restraints to be used for all vehicular applications.

7. Compacting of the area can be done using an appropriate compacting plate with the plate covered with a soft layer of material to avoid chipping the surface of the products

(i.e. carpet).

8. The joints between the product should be between 3 and 5 mm and can be filled after compaction with appropriate

jointing sand swept into the joints. Spread dry sand over the paved area and brush it into the vertical joints with a stiff bristled broom. Clean the area of excess sand before final compaction.

9. Jointing sand facilitates the interlock between units and promotes controlled movement. It is recommended to leave a 10 mm gap between pavers every 8 metres.

10. Regular checks should be done to ensure that the paving is performing as desired and any maintenance should be carried out to ensure the structural integrity of the paved area.

$163.90 per m3

$27.45 each

$23.81 each